automatic capsule filling machine working principle

Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. You can also look for the automatic capsule filling machine through the web.

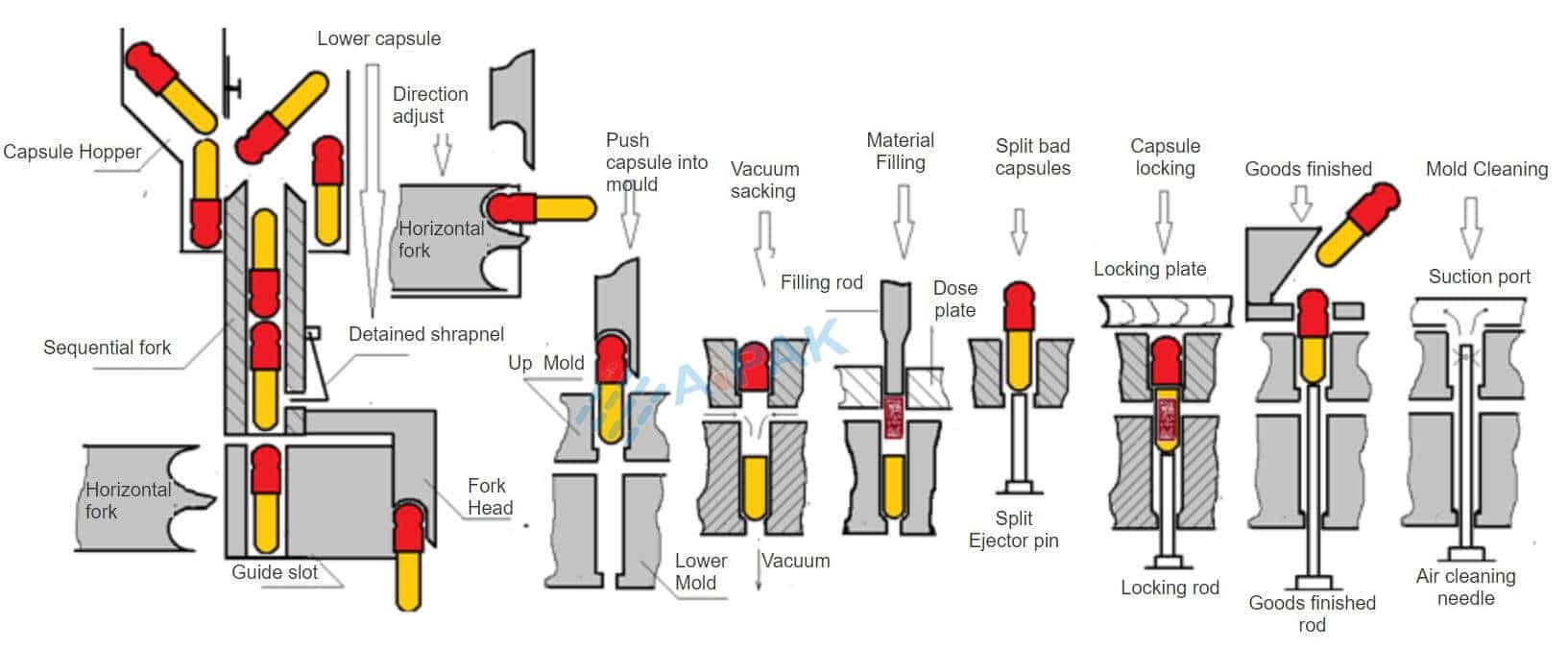

Rectification where the machine automatically orients the capsules.

. Aipak NJP-800 capsule filling machine manufactured by our company has been improved and innovated for several years. The principles of the machines are as follows. Personal capsule filling machines is for small scale production and utilization.

This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight when the amount of pressure of the liquid reservoir is equal to the. Hereyou will see most of your empty capsules are connected capsules as whose body and cap are joined together originally. After that the material is filled in the capsules with the help of powdergranule filler present in the capsule filler machine then the caps and body are rearranged in the machine itself.

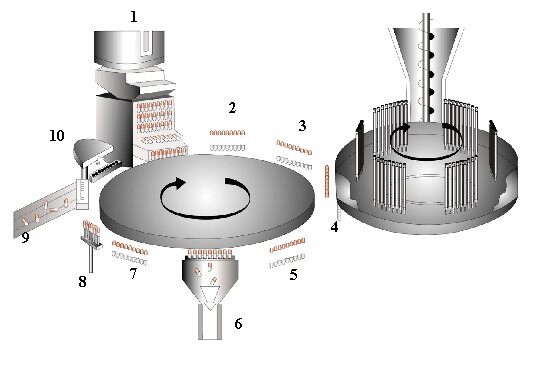

It has 9 holes turning out a highest output of 1200 capsulesminute. The SF-135N capsule filling machine is used for various industries like chemical pharmaceutical animal food and food. It not only has all kinds of performance and technical standards of the same type 800 in China.

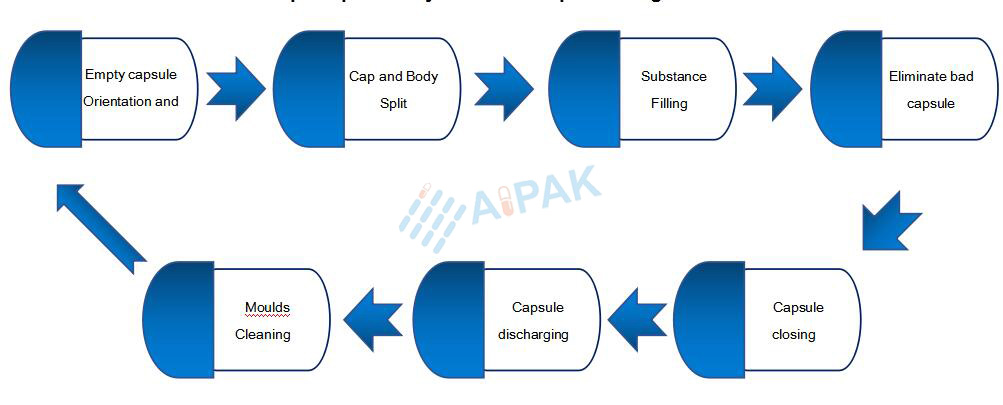

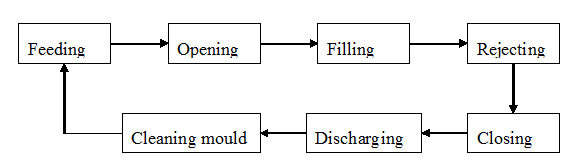

Liquid Filling Machine Its Principles. Whether you choose a dosator or tamping pin type capsule filler the sequence remains the same. Automatic capsule filling machine is a kind of professional capsule filling equipment fully automatic capsule filling machine is mainly in medicine department of pharmaceutical preparation in hospital health care products and other industries for powder or micro pill capsule filling of the drug it adopted the hole and the stowing intermittent motion and so on can be.

Put the lower mold to the turntable and add the powder to the hopper. Capsule filler is a type of machine used to fill empty capsules with pharmaceutical ingredients. Although the production cost increases we have significantly enhanced the devices production efficiency and service life.

Cover the filled lower mold with the upper mold and move them to the locking. A capsule filling machine can be of three types- manual semi-automatic automatic depending upon the operation. First the capsule caps are divided from their bodies.

For pellet filling the maximum capacity is 95000. The liquid filling machine works when the pressure is high. Contact Us Send Inquiry.

The capsule filling machine is an automatic capsule filling machine by which the separation filling and sealing of capsules can be carried out automatically. This machine can produce a maximum of 135000 caphr. Due to these advantages it has been widely received by customers at home and abroad.

Its filling speed has been raised up to about 1100pcs capsule per minutes. Now the third generation of 800 fully automatic capsule filling machines have advanced technology and excellent configuration. These capsules fillers are divided into 2 categories depending upon their uses ie personal capsule filling machine professional capsule filling machine.

Filling is possible through exchanging of parts. And then the capsules are processed out as the ready. Generally the process of filling capsules involves.

Aipak automatic capsule filling machine working principle. For capsules with good quality the machine can be run fast while the machine shall run relatively slowly if the capsule quality is not good. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding.

Working Principles of Various Filling Machines. The rate of filling the capsules with the powdered content differs with the. Press the filling button ON to fill the capsule.

The machine can greatly improve production efficiency and reduce labor costs. This section is the empty capsule feeding mechanismwhich is to load the empty capsules into the mold for the next procedure body and cap separation. NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole.

Filling Machines Their Working Principles

Encapsulators Operating Principles Types And Sequence Of Events

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Automatic Capsule Filling Machine Manufacturer Upmach

Automatic Capsule Filling Machine Working Principle Pharmaceutical Updates

Semi Automatic Capsule Filling Machine Saintytec

Capsule Filling Machine Working Principal Functional Principle Capsule Filling Process Youtube

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine Working Principle Ipharmachine

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

How Different Types Of Capsule Filling Machine Work

Automatic Capsule Filler Encapsulation Machine Njp 1200c Ipharmachine

Tamping Pin Type Capsule Filling Machine Working Principle

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Capsule Filling Machine Your Best Online Resource About Capsule Fillers